What is a sandwich panel?

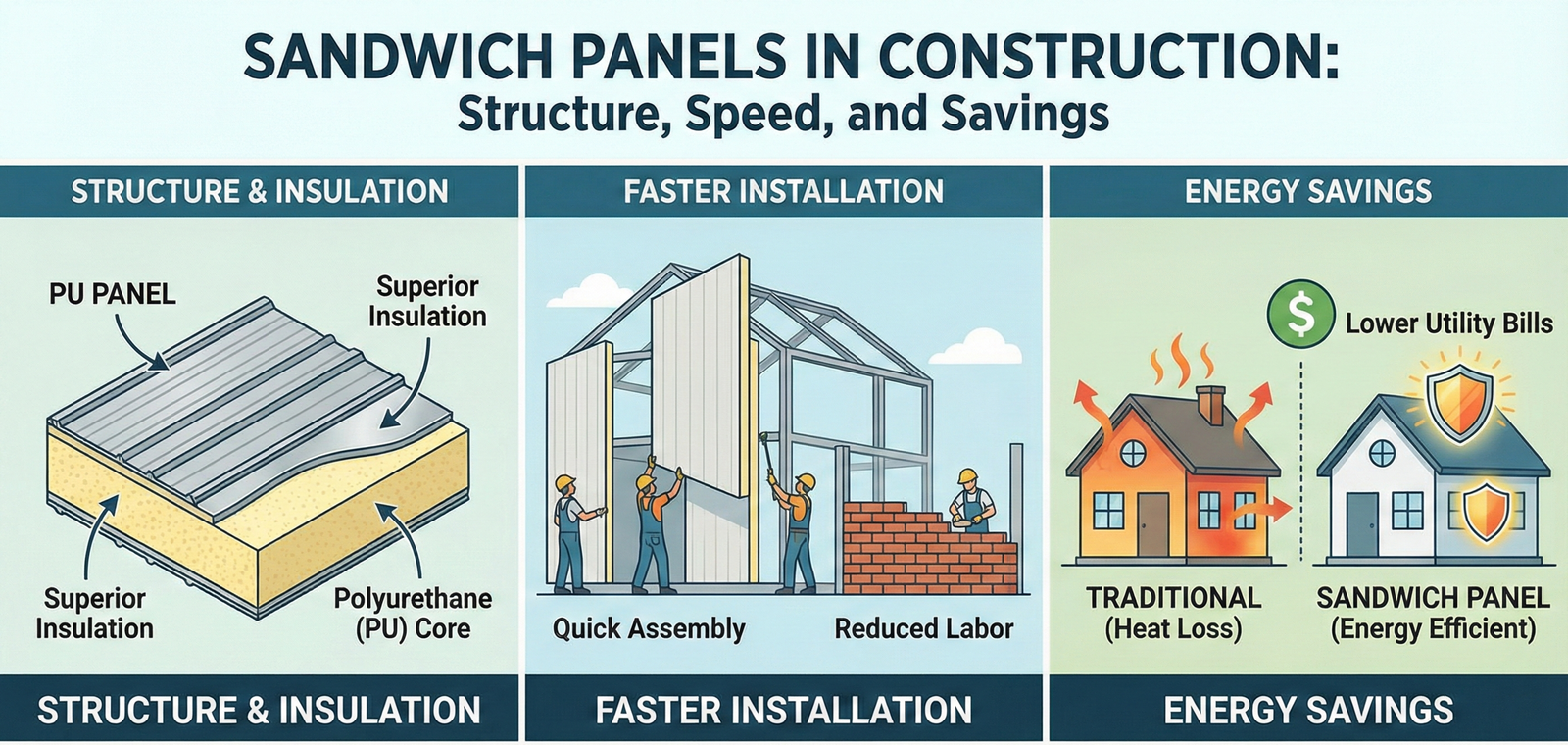

Uncover how these superior insulation panels, like PU panels, revolutionize construction with faster installation and energy savings

Imagine a world where buildings go up faster, stay warmer in winter, cooler in summer, and even use less energy. Does that sound like a dream? Well, it’s actually happening right now, thanks to some clever building materials! We are talking about something amazing called a sandwich panel.

A sandwich panel is a truly smart invention. Think of it like a giant, super-strong sandwich for your building. It’s a special kind of lightweight building material, made from two tough outer layers that hug a soft but strong core material in the middle. This clever design makes them lightweight, yet also very sturdy.

These incredible sandwich panels are really changing how we build things today. They are super versatile and perform really well in many different kinds of projects. Importantly, they bring many good things to the table. These benefits include excellent thermal insulation, meaning they keep heat in or out very well, amazing structural strength, and they are also surprisingly easy to handle during the installation panel process.

So, in this guide, we’re going to take a closer look at what these powerful sandwich panels actually are. We will explore their different types, spending special time on the super-efficient PU panels. You will discover why they are known as top-notch insulation panels, and we will also share some really important tips for their installation panel. Get ready to uncover the secrets of modern building!

1. What Exactly is a Sandwich Panel?

Let’s begin by understanding what a sandwich panel truly is. Picture it like this: a composite panel is a special building block that is made from different parts put together. In this case, it means two thin, very strong outside layers are firmly stuck to a softer material in the middle. This combination creates a panel that is both light to carry and very stiff. It also has fantastic insulating properties, which means it helps keep buildings warm or cool.

Indeed, a sandwich panel is a masterpiece of modern engineering. It’s designed to give you the best of many worlds: lightness, strength, and great insulation, all in one handy package. This structural insulated panel helps builders create better, more energy-efficient spaces.

Core Components Explained

Just like a sandwich has different yummy layers, a sandwich panel has its own important parts. Let’s break down what these crucial components are and what they do.

Facings (Skins)

First, we have the facings, also known as skins. These are the two outer layers of the sandwich panel. Think of them as the protective bread slices of our building sandwich. Usually, these skins are made from tough materials like:

- Pre-Painted Galvanized Steel (PPGI): This is steel that has been treated to stop rust and then painted. It’s very common because it’s strong, lasts a long time, and looks neat.

- Aluminum: This metal is lighter than steel but still very strong. It’s great for places where weight matters.

- Stainless Steel: This type of steel is super good at resisting rust and stains. It’s often used in places where cleanliness is very important, like kitchens or hospitals.

- Fiberglass Reinforced Plastic (FRP): This material is made from plastic with tiny glass fibers inside, making it very tough. It’s also good for places that need to be clean and can handle moisture well.

These facings do a lot of important jobs. They give the sandwich panel its main strength and stiffness. They also protect the inside part from weather and damage. What’s more, the facings are what you see on the outside, so they give the building its look and style.

Core Material

Now, let’s talk about the heart of the sandwich panel – the core material. This middle layer is where most of the panel’s special abilities come from, especially its insulation power. Many types of materials can be used for the core, each with its own benefits:

- Polyurethane (PU) Foam: This is a fantastic material, widely known for being one of the best at stopping heat from moving. It makes PU panels super-efficient

insulation panels. We will learn much more about these in the next section because they are so popular and effective. - Mineral Wool: Imagine fluffy rocks that don’t burn! Mineral wool is excellent if you need really good fire protection. It also helps a lot with stopping sound, making buildings quieter.

- Expanded Polystyrene (EPS): This is often called Styrofoam. It’s a lighter, more affordable option that still provides good thermal insulation. It is a cost-effective choice for many construction projects.

- Polyisocyanurate (PIR): This material is very similar to PU foam, but it’s been specially made to be even better at resisting fire. So, it gives enhanced fire safety compared to standard PU.

Indeed, the choice of core material directly impacts how the sandwich panel will perform. For instance, a panel with a PU core will be a fantastic thermal panel, while a mineral wool core will excel in fire safety and noise reduction.

Adhesive

Finally, we have the adhesive. This is the super-strong glue that holds everything together. The adhesive makes sure that the two outer facings are stuck very firmly to the core material. This strong bond is super important for the whole panel to work properly. Without a good adhesive, the sandwich panel wouldn’t be strong or last as long. It is truly essential for the structural integrity and durability of these composite building materials.

So, a sandwich panel is a clever combination of strong outer skins, a performance-driven core, and a powerful adhesive, all working together to create a superior building material.

2. Delving Deeper: Types of Insulation Panels with a Focus on PU Panels

When we talk about keeping buildings warm in winter and cool in summer, we’re really talking about insulation panels. This is a big group of materials designed to stop heat from moving. Among all the different kinds, sandwich panels stand out as a super effective form of insulation. This is mainly because their parts are all built together, creating a strong, ready-to-use piece that provides excellent thermal resistance. They are truly integrated thermal panels.

For many building projects today, these pre-fabricated panels are a top choice.

Focus on PU Panels

Now, let’s shine a spotlight on a very special type of sandwich panel – the PU panels. These panels are incredibly popular for a good reason, mostly because they are incredibly good at insulating.

Definition of PU Panels

What exactly are PU panels? Well, a PU panel is simply a specific kind of sandwich panel where the soft, middle core material is made from Polyurethane (PU) foam. This special foam is either squirted in (injected) or continuously formed right between the two metal outer layers, bonding them together perfectly. It creates a unified, high-performance insulation board that is ready for building.

Key Characteristics of PU

Polyurethane foam has some truly amazing characteristics. The most important one is that it’s a “closed-cell” material. What does this mean? Imagine lots and lots of tiny, tiny bubbles of gas, all trapped inside the foam, like miniature balloons. These little pockets of gas are fantastic at holding heat in place. They prevent heat from easily moving through the material. This is why PU foam is so brilliant at keeping buildings at a steady temperature. It’s like having a million tiny air blankets all working together.

Advantages of PU Panels

Because of their special PU foam core, PU panels offer a lot of great benefits. This makes them a top choice when you need super-efficient insulation panels.

- Exceptional Thermal Insulation: This is perhaps the biggest superpower of PU panels. PU foam has one of the lowest thermal conductivity values (we often use the Greek letter λ, pronounced “lambda,” for this). This number tells us how easily heat can pass through a material. A low lambda value means heat struggles to get through. Therefore, PU panels are highly efficient

insulation panels. They are really good at keeping indoor temperatures just right, whether it’s hot outside or freezing cold. This, in turn, helps buildings use much less energy for heating and cooling, saving a lot of money on utility bills. - Lightweight: Even though they are very strong and provide amazing insulation, PU panels are surprisingly light. This makes them much easier to move around, lift, and work with during the `installation panel` process. Lighter materials also mean less strain on the building’s main structure.

- High Strength-to-Weight Ratio: This is a fancy way of saying they are very strong for how light they are. PU panels can support a good amount of weight and span wide spaces without needing extra support. This makes them great for building strong walls, sturdy roofs, and ceilings.

- Moisture Resistance: Because of that special closed-cell structure we talked about, PU foam doesn’t soak up much water. This is fantastic! It means `PU panels` keep their insulating power even in damp places. Also, it helps stop mold and mildew from growing, which keeps buildings healthier and cleaner. It also means they act as an effective vapor barrier.

- Durability: PU panels are built to last a long, long time. They don’t easily break down or lose their insulating abilities over many years. This means once they are installed, they will keep doing their job well for decades, offering sustained thermal performance.

Applications of PU Panels

Due to their superior qualities, especially their thermal performance, PU panels are used in many different types of buildings and projects. They are highly sought after as efficient thermal panels.

- Cold Storage Facilities and Freezers: This is one of the most common places you’ll find PU panels. Because they are so incredibly good at keeping cold in (or heat out), they are perfect for giant refrigerators and freezers where food and other sensitive items need to stay at very low temperatures.

- Cleanrooms and Pharmaceutical Facilities: In places where it’s super important to keep things clean and controlled, like laboratories or medicine factories, PU panels are a great choice. Their smooth surfaces are easy to clean, and their insulation helps maintain steady temperatures.

- Industrial Buildings: For factories, warehouses, and other industrial sites, PU panels are used for walls, roofs, and ceilings. They help create comfortable working environments and save energy for heating or cooling large spaces.

- Food Processing Plants: Similar to cold storage, these panels are ideal for food processing areas. They meet strict hygiene rules and help control temperatures for food safety.

- Commercial Buildings and Prefabricated Structures: From offices to shops, and even buildings that are built in parts off-site and then put together, PU panels are used to make them energy-efficient and durable.

In short, `PU panels` are a fantastic solution for many building needs, providing top-tier insulation and structural integrity.

Other Common Insulation Panels

While PU panels are outstanding, it’s good to know about a couple of other important types of insulation panels too, based on their core materials.

- Mineral Wool Panels: These panels are highly valued because they do not catch fire easily. They are known for being non-combustible, which is extremely important for building safety, especially in places where fire protection is a top priority. They also do an excellent job of blocking sound, helping to make buildings much quieter and more peaceful inside.

- EPS Insulation Panels: These are often chosen because they are more affordable. While they might not insulate quite as well as `PU panels`, they still offer good thermal performance and are a cost-effective option for projects where the very highest level of insulation isn’t needed. They are a practical solution for many standard building applications.

Therefore, choosing the right insulation board depends on the specific needs of a project, balancing factors like cost, thermal resistance, and fire safety.

3. The Multifaceted Benefits of Sandwich Panels

Sandwich panels are much more than just simple building blocks; they offer a wide range of advantages that make them a smart choice for many construction projects. Let’s explore the many good things these innovative building materials bring.

Superior Thermal Insulation

One of the greatest benefits of sandwich panels is their incredible ability to insulate. These composite panels, especially those with PU panels at their core, significantly reduce how much heat can pass through walls and roofs. This means that during hot summer days, less heat gets into the building, and in cold winters, less warmth escapes. The result? Buildings stay more comfortable inside, and less energy is needed to heat or cool them. This directly leads to lower energy bills and helps the environment by using less power. They truly are superior insulation panels.

Indeed, their excellent thermal performance helps create more sustainable and energy-efficient structures.

Rapid Installation & Construction

Another huge advantage is how quickly sandwich panels can be put up. Because they are prefabricated, meaning they are made in a factory beforehand, they arrive at the construction site ready to be installed. This “ready-to-use” nature means that buildings can be constructed much faster compared to traditional ways of building, which often involve many different steps and materials being assembled on site. Faster building times mean less money spent on labor and projects finish much sooner. This is a key benefit of using an efficient installation panel system. Therefore, they speed up project timelines considerably.

High Structural Strength and Load-Bearing Capacity

Even though sandwich panels are lightweight, don’t let that fool you! Their clever composite design, with two strong outer layers and a sturdy core, gives them excellent rigidity and strength. This means they are very capable of supporting weight and can span quite large distances without needing a lot of extra support beams. They provide fantastic structural stability, making them suitable for robust building envelopes. So, they offer both lightness and impressive strength for the overall building structure.

Acoustic Comfort

Many types of sandwich panels also help make buildings quieter. Panels that use mineral wool for their core, for example, are very good at soaking up sound. This means they can reduce noise coming from outside the building, like traffic, and also stop sound from traveling between different rooms or floors inside. This leads to a more peaceful and comfortable environment for everyone inside, enhancing the overall comfort and productivity. The noise reduction they provide is a significant advantage.

Fire Safety

While PU panels offer good resistance to fire, it’s important to know that some core materials are designed to be even better. For instance, mineral wool and PIR (Polyisocyanurate) cores are specially made to have enhanced fire resistance. This is extremely important for the safety of people and property in various types of buildings, ensuring that structures meet stringent building safety codes. So, depending on what fire protection is needed, there’s a sandwich panel solution available.

Durability and Longevity

Sandwich panels are built to last. They are made from high-quality materials that are tough and resistant to many common problems. This includes resistance to rust (corrosion), bad weather like heavy rain or strong sun, and even pests like insects. Because they are so durable, they have a very long service life and don’t need much maintenance over the years. This makes them a wise, long-term investment for any building project, offering consistent thermal performance.

Aesthetic Versatility

Lastly, sandwich panels are not just practical; they can also look great! They come in a wide range of colors, different finishes (like smooth or textured), and various shapes or profiles. This means architects and builders have a lot of freedom to create modern and attractive building designs. Whether you want a sleek, contemporary look or something more traditional, there’s a sandwich panel that can fit the style you need. They provide vast design flexibility for building facades.

All these benefits show why sandwich panels are becoming an increasingly popular choice in the world of construction. They offer a comprehensive solution that addresses many modern building needs.

4. Key Considerations for Installation Panel Systems

Getting your sandwich panels installed correctly is just as important as choosing the right ones. Proper installation panel practices ensure that the panels perform their best, providing all the thermal insulation, strength, and durability you expect. Let’s look at the key things you need to think about for a successful installation panel system.

Site Preparation

Before any sandwich panel goes up, the building site needs to be perfectly ready. This is the very first and most crucial step. It’s absolutely essential to have a very level and stable foundation. Or, if you’re attaching them to a frame, that support structure (like a steel framework) must be strong, straight, and properly aligned. If the base isn’t right, the sandwich panel won’t fit together well, which can cause problems later on with its strength and how well it insulates. For example, a wavy foundation can lead to gaps, which will then compromise the thermal performance of your `insulation panels`.

Handling and Storage

Sandwich panels need to be treated with care, just like any valuable building material. When you move them, be gentle! It’s very important to prevent any damage, like scratches or dents, to the outer facings or the edges. These panels should always be stored properly. This means placing them on flat surfaces to stop them from bending, and importantly, protecting them from bad weather like rain or direct strong sunlight. Leaving them exposed can damage the facings or even the core, which will affect their longevity and how well they perform as `insulation panels`.

Lifting and Positioning

Because sandwich panels can be large and sometimes heavy, especially for big building projects, special equipment might be needed to lift and put them into place. This often includes vacuum lifters, which gently grip the panels, or cranes with the right kinds of slings. Using the correct tools and techniques for lifting and positioning ensures that the `installation panel` process is safe and efficient. It also helps prevent any accidental damage to the panels during transport from storage to the actual building frame.

Fastening Methods

Once the panels are lifted, they need to be securely attached to the building’s structure. There are different ways to do this, using various fastening methods. Common ways include using self-drilling screws that come with special washers to create a tight seal, clips that hold the panels in place, or even hidden (concealed) fasteners for a very clean look. The specific type of fastener used will depend on the kind of sandwich panel you have and what the building’s structural needs are. It’s also super important to use the correct amount of tightness (torque settings) when screwing them in. If they are too loose, they won’t hold well; if too tight, you could damage the panel.

Joint Sealing

This step is truly critical for the long-term performance of your building’s sandwich panel system. Once panels are in place, the spaces where they meet (the joints) must be sealed perfectly. This is vital for two main reasons: maintaining excellent thermal performance and ensuring weather resistance. Builders use special sealants, like silicone or sticky butyl tapes, and gasket systems to create joints that are both airtight and watertight. A good seal stops heat from escaping or entering (this is called preventing thermal bridging) and also stops moisture, like rain, from getting inside the building. Without proper joint sealing, even the best `PU panels` will lose their insulating power.

Cutting and Detailing

Sometimes, sandwich panels need to be cut to fit around windows, doors, or corners, or to create specific shapes. It’s important to use the right tools for these jobs, such as jigsaws or circular saws with fine-tooth blades, to get a clean and precise cut. Accurate cutting and careful detailing around openings are essential. Not only does this make the building look neat and finished, but it also helps maintain the thermal integrity and weather protection of the sandwich panel system. Precise detailing is key for both aesthetics and functionality.

Safety Precautions

Lastly, safety must always come first on any construction site. When working with installation panel systems, it’s very important that everyone wears the right safety gear. This includes things like hard hats (helmets), tough gloves to protect hands, and safety footwear. Everyone must also strictly follow all the site’s safety rules and protocols. Working safely protects everyone involved and helps ensure the project runs smoothly without accidents. Therefore, never skip safety checks during the entire `installation panel` process.

By paying close attention to these key considerations, builders can ensure that their sandwich panels, including `PU panels`, are installed correctly, giving the building maximum benefits as high-performance `insulation panels` for many years to come.

Conclusion

So, we have journeyed through the fascinating world of sandwich panels, uncovering just how powerful and versatile these materials truly are. We’ve seen that they are truly modern marvels in construction.

To recap, the primary benefits of using these smart, prefabricated panels are clear: they offer exceptional thermal insulation, making them super-efficient insulation panels that save energy and lower costs.We highlighted the superior performance of PU panels, especially for keeping temperatures steady in demanding environments. Furthermore, we discussed how their integrated design makes the entire construction process much faster and easier, streamlining the installation panel process.

Moreover, these panels are incredibly versatile. They play a vital role in a wide range of construction sectors, from large industrial facilities and super-cold storage buildings to state-of-the-art cleanrooms and sleek, modern architectural designs. Their adaptability means they can be used almost anywhere, meeting various needs with ease.

In the end, sandwich panels represent a smart, sustainable, and high-performance choice for building envelopes today. They offer a durable, energy-efficient, and aesthetically pleasing solution for almost any project.

Are you thinking about your next building project? Then it’s time to consider the immense benefits that sandwich panels can bring. If you have specific needs or questions, don’t hesitate to consult with experts who can guide you to the perfect sandwich panel solution. They can help you achieve the best results for your unique application!