The Ultimate Guide to Sandwich Panels: Understanding Insulation, Installation, and PU Technology

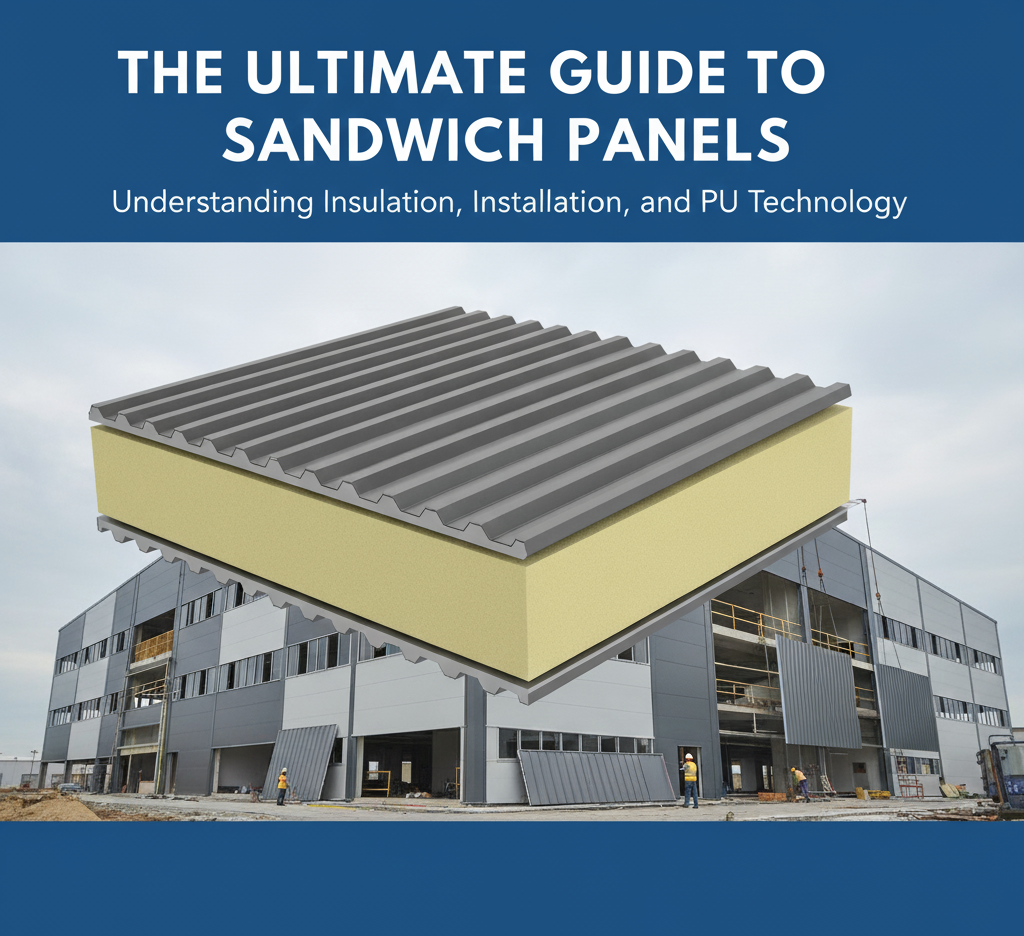

Have you ever wondered how some buildings stay so cool in the summer and warm in the winter? Or how a new factory can go up so quickly? Often, the secret lies in a clever building material called a sandwich panel. These amazing sandwich panels are much more than just simple building blocks; they are engineered solutions that make our modern buildings better, stronger, and more energy-efficient.

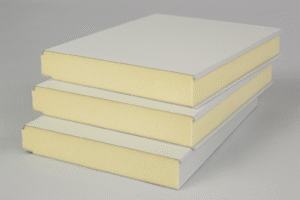

A sandwich panel is a special kind of building part, like a layered cake for a wall or roof. Think of it as a smart, composite structure made of three distinct layers. At its heart is a soft, light middle part, much like an insulation panel. This core is tucked neatly between two harder, thinner outer skin layers. Together, these layers work in harmony, creating a powerful component.

These clever panels are used everywhere in today’s construction world. They help keep buildings warm or cool, give them strength, and even make them look nice. From big warehouses to small offices, you’ll spot them in action. They are particularly vital for their fantastic thermal insulation, making them truly effective as insulation panels. Furthermore, they add to the structural strength of a building, and with many finish options, they offer great aesthetic appeal.

This blog post will take you on a journey to understand these incredible building components. We will pull back the curtain on sandwich panels, explore specific types like the popular PU panels, and grasp their crucial role as top-notch insulation panels. We will also give you clear insights into their straightforward installation panel process. Get ready to learn all about how these panels are shaping the future of building!

What Exactly is a Sandwich Panel?

Let’s start by getting a crystal-clear picture of what a sandwich panel truly is. Imagine a delicious sandwich you might eat for lunch. It has two slices of bread with a tasty filling in the middle. A building sandwich panel works in a very similar way, but instead of bread and filling, it uses high-tech materials designed for construction.

Essentially, a sandwich panel is a cleverly designed composite material. “Composite” means it’s made by combining different materials together to get the best qualities of each. This engineered building component consists of a central core, which is always made of a lightweight, low-density material. This core is then securely bonded, or glued, between two outer layers. These outer layers are known as facings or skins, and they are typically made from a different, much stiffer material than the core. This smart layered construction gives the panel a fantastic combination of qualities. It provides a very high stiffness for its weight and boasts excellent thermal properties, meaning it’s great at stopping heat from passing through. These composite panels are truly a marvel of modern engineering, offering a robust yet light solution for various building needs.

Structure Explained: Unpacking the Layers

To really understand how a sandwich panel works, we need to look closer at its three main parts. Each part has a specific job, and they all work together to make the panel strong, insulating, and long-lasting.

Facings (or Skins)

Think of the facings as the “bread” of our sandwich panel. These are the outer layers that you see and touch. They are typically thin but incredibly strong. The materials used for these skins are chosen for their durability, ability to resist weather, and often for how they look.

- Pre-Painted Galvanized Iron (PPGI): This is a very common choice. It’s steel that has been coated with zinc (galvanized) to stop it from rusting, and then painted in a factory with a special durable paint. PPGI skins offer great strength, weather resistance, and come in many colors, making them highly versatile for many projects.

- Stainless Steel: For places that need extra cleanliness or have harsh chemicals, stainless steel skins are used. They are super resistant to rust and very easy to keep clean. This makes them perfect for food processing plants or hospitals.

- Aluminum: Lightweight and corrosion-resistant, aluminum facings are another excellent option. They are often used when weight is a critical factor, or in environments where salt spray or certain chemicals might be present.

- Fibre Reinforced Plastic (FRP): FRP skins are made from plastic strengthened with fibers. These are very strong, durable, and resistant to many chemicals. They are often chosen for agricultural buildings or areas that need to be washed down frequently.

These facings provide much more than just a pretty exterior. They give the sandwich panel its structural rigidity, meaning they help the panel hold its shape and resist bending. They also protect the inner core from rain, wind, and sun, ensuring the panel lasts for many years.

Core Material

Now, let’s talk about the “filling” – the central core layer. This is arguably the most important part when it comes to a panel’s performance, especially its ability to insulate. This is where the whole idea of insulation panels truly comes to life. The core material is chosen specifically for its low density and its ability to trap air or gas, which slows down the transfer of heat.

- Crucial for Insulation: The primary role of the core is to provide excellent thermal insulation. It acts as a barrier, preventing heat from escaping in winter or entering in summer. This makes buildings much more comfortable and saves a lot of energy.

- Contributing to Structural Integrity: While lightweight, many core materials also contribute to the panel’s overall stiffness and strength. They help space out the two strong facings, making the whole composite panel incredibly rigid. Imagine trying to bend two thin sheets of metal; it’s easy. Now imagine those two sheets separated by a thick layer of foam, glued together; it’s much harder to bend. This is the “sandwich effect” at work, creating a very strong, yet light, building element.

Different core materials offer different levels of insulation, fire resistance, and cost. Choosing the right core is key to getting the best performance from your insulated panel. We will explore these core types in more detail very soon. Understanding the roles of both the facings and the core helps us appreciate the clever design of these construction panels. They are engineered to perform, making them a cornerstone of modern, efficient building practices.

The Heart of the Panel: Types of Insulation Cores

The middle layer, the core, is what truly defines an insulation panel. It’s the engine room, so to speak, determining just how well the panel keeps warmth in or out. The choice of core material directly impacts the thermal performance of the entire sandwich panel. Each core type offers unique benefits, making them suitable for different kinds of buildings and specific needs.

Polyurethane (PU) Panels: The Insulation Champion

When you hear about really effective insulation panels, PU panels are often at the top of the list. They are a standout choice because of their incredible insulating power.

- Definition: PU panels get their name from their core material: Polyurethane foam. This isn’t just any foam; it’s a special type of closed-cell foam. “Closed-cell” means that tiny pockets of gas are sealed within the foam structure. These gas pockets are fantastic at stopping heat from moving through, making polyurethane a superb insulator.

- Properties that Make Them Shine:

- Exceptional K-value (Thermal Conductivity): The K-value tells us how well a material conducts heat. A low K-value means the material is a very poor conductor of heat, which is exactly what you want for insulation. Polyurethane foam has one of the lowest K-values among common insulation materials, making PU panels incredibly efficient at blocking heat flow. This superior thermal resistance directly translates into energy savings.

- Lightweight: Despite their impressive strength and insulating power, PU panels are surprisingly light. This lightness makes them easier to handle during construction, reduces the load on the building’s main structure, and can even save on transport costs.

- Good Compressive Strength: This means the foam can withstand a lot of pressure without squashing. This structural rigidity helps the entire sandwich panel maintain its shape and strength, especially in wall and roof applications where they might support weight or resist wind pressure.

- High Resistance to Moisture Absorption: Polyurethane foam doesn’t soak up water easily. This is a huge advantage, as wet insulation loses much of its insulating power. This resistance also helps prevent mold growth and keeps the panel durable over time, making these insulated panels a robust choice for various climates.

- Advantages:

- Superior Energy Efficiency: Because of their very low thermal conductivity, thermal panels dramatically reduce the amount of energy needed to heat or cool a building. This means lower utility bills and a smaller environmental footprint. These are truly game-changers for energy savings.

- Ideal for Temperature-Controlled Environments: If you need to keep things precisely cold (like a freezer room) or warm (like a clean room), PU panels are often the first choice. Their consistent and high-performance insulation makes them indispensable for cold storage facilities, food processing plants, and pharmaceutical clean rooms.

Other Common Core Materials (Briefly)

While PU panels are stars, other core materials also play important roles, offering different balances of cost, performance, and specific features. These insulation panels provide architects and builders with a range of options.

- Expanded Polystyrene (EPS):

- What it is: EPS foam is made of tiny plastic beads that are expanded with steam and molded together. You might recognize it as the material used in disposable coffee cups or packaging foam.

- Key Features: It offers good insulation properties and is very lightweight. Critically, EPS is often more cost-effective than other core materials, making it a popular choice for budget-conscious projects. These styrofoam core panels are widely used where good, but not necessarily extreme, insulation is required.

- Applications: Commonly found in general-purpose industrial buildings and some residential applications.

- Mineral Wool (Rock Wool/Glass Wool):

- What it is: Mineral wool cores are made from natural or synthetic minerals (like basalt rock or glass) that are melted and spun into fine fibers. These fibers are then compressed into rigid boards.

- Key Features: Its fibrous structure provides excellent fire resistance, often making it the preferred choice where fire safety regulations are very strict. It also offers good acoustic insulation, helping to dampen sound, in addition to its thermal insulation properties. These fire-rated panels are essential in many commercial and industrial settings.

- Applications: Ideal for buildings where fire safety is paramount, such as factories, power plants, and public buildings.

- Polyisocyanurate (PIR):

- What it is: PIR foam is closely related to polyurethane foam. It’s an improved version, chemically modified to enhance its fire resistance.

- Key Features: PIR maintains excellent thermal performance, very similar to PU, but with significantly improved fire performance. It chars in a more stable way when exposed to fire, rather than melting or dripping. This makes it a safer option in many commercial and industrial buildings. These PIR core panels combine high insulation with enhanced safety.

- Applications: Increasingly used in applications where both high thermal performance and superior fire safety are required, bridging the gap between standard PU and mineral wool.

The diversity of core materials highlights how versatile sandwich panel technology is. Each core offers a tailored solution, allowing builders to select the perfect insulation panel for their specific project, whether it’s a deep freezer, a quiet office, or a fire-resistant wall.

Focus on PU Panels: The High-Performance Choice

Among the various types of insulation panels, PU panels hold a special place. They are truly the high-performance choice for many demanding applications in the construction world. Builders and architects highly value these panels for a very good reason: their exceptional qualities deliver outstanding results. Let’s explore why PU panels are considered a superior option and why they are so widely adopted.

Unrivaled Thermal Performance

The standout feature of PU panels is their incredible ability to block heat transfer. This makes them one of the most efficient insulation panels you can find.

- Low Thermal Conductivity: At the heart of their performance is Polyurethane foam’s very low thermal conductivity. This value, often around 0.023 Watts per meter-Kelvin (W/mK), is one of the lowest in the insulation industry. To put this simply, it means very little heat can pass through the foam.

- Significant Energy Savings: What does this low thermal conductivity mean for a building? It translates directly into substantial energy savings. In cold climates, PU panels keep the warmth inside, reducing the need for constant heating. In hot climates, they prevent outside heat from entering, keeping the interior cool with less air conditioning. Over the lifespan of a building, these energy-efficient panels can lead to enormous reductions in electricity and heating fuel bills. They are a smart investment that pays for itself over time through lower operational costs.

- Stable Indoor Temperatures: Beyond just saving money, the superior insulation provided by PU panels creates a much more stable and comfortable indoor environment. Fewer temperature fluctuations mean better conditions for people, products, or sensitive equipment stored inside. This consistent temperature control is crucial in many industrial settings.

Versatility Across Applications

PU panels are not just for one type of building; they are incredibly versatile. Their excellent performance makes them suitable for a wide array of applications that require stringent temperature control.

- Cold Storage: This is where PU panels truly shine. They are the go-to material for cold rooms, freezer rooms, and chilling facilities. Their ability to maintain very low temperatures consistently is unmatched, protecting perishable goods like food, medicines, and chemicals. These refrigeration panels ensure product quality and safety.

- Food Processing Units: In environments where hygiene and temperature are critical, PU panels provide the controlled conditions needed for food preparation and packaging.

- Clean Rooms: For industries like pharmaceuticals, electronics, and medical research, clean rooms are essential. PU panels help create these controlled environments, which require stable temperatures and humidity levels, free from contaminants.

- Industrial and Commercial Buildings: Beyond specialized uses, PU panels are increasingly found in general industrial buildings, warehouses, and even commercial complexes, where energy efficiency and indoor comfort are priorities. Their adaptability makes them a preferred choice for modern, high-performance building envelopes.

Durability and Longevity

Investing in building materials means you want them to last. PU panels are known for their impressive durability, contributing to a longer lifespan for the entire building structure.

- Resistance to Chemicals: Polyurethane foam is resistant to many common chemicals. This makes PU core panels suitable for industrial environments where exposure to certain substances might be a concern.

- Resistance to Fungi and Pests: Unlike some organic insulation materials, polyurethane foam does not provide a food source for fungi, mold, or pests. This intrinsic resistance helps maintain indoor air quality and prevents structural degradation over time. It means less worry about maintenance and repairs related to biological growth.

- Structural Integrity: The closed-cell structure and good compressive strength of the foam, combined with robust facings, ensure that the sandwich panel remains structurally sound and performs consistently for many years, even decades. This long-term performance makes them a reliable and sustainable choice.

Lightweight Advantage

Despite their strength and insulating power, PU panels are surprisingly light. This lightness offers several practical benefits during the construction process and for the building itself.

- Ease of Handling: Lighter panels are much easier to lift, move, and position on a construction site. This reduces the physical strain on workers and can speed up the installation panel process significantly.

- Reduced Structural Load: Because the panels are lightweight, they impose less overall weight on the building’s foundation and main structural framework (like steel beams or concrete columns). This can potentially lead to savings in the design of the supporting structure, as less heavy-duty components might be needed. Lighter structures can also be built on less robust foundations, saving both time and money.

- Faster Construction: The combination of being lightweight and prefabricated means that PU panels can be installed very quickly. This contributes to shorter project timelines and reduced labor costs, making the entire building process more efficient.

In summary, PU panels offer a compelling package of benefits. Their top-tier thermal performance, wide versatility, inherent durability, and lightweight nature make them an exceptional choice for a vast range of construction projects. When you need an insulation panel that truly performs, PU panels are often the answer, driving energy savings and enhancing building quality for years to come.

Key Benefits of Utilizing Sandwich Panels in Construction

Choosing sandwich panels for a building project brings a host of advantages that traditional construction methods often struggle to match. These modular building panels are not just a trend; they are a smart, efficient, and forward-thinking solution for modern construction challenges. Let’s dive into the core benefits that make them such a popular and valuable building material.

Superior Thermal Insulation

One of the most compelling reasons to use sandwich panels is their outstanding ability to insulate. This is crucial for creating comfortable, energy-efficient buildings.

- Exceptional Core Materials: As we’ve discussed, the core material is key. Especially with PU panels (Polyurethane) and PIR panels, the thermal resistance is incredibly high. These materials are engineered to be poor conductors of heat.

- Reduced Heat Transfer: The layered design significantly reduces heat transfer, meaning less heat escapes a building in winter and less heat enters in summer. This translates directly into substantial savings on energy bills. Buildings become easier and cheaper to heat and cool, leading to lower operational costs over their entire lifespan. These insulated building panels make a real difference in long-term expenses.

- Thermal Breaks: The way sandwich panels are designed inherently minimizes “thermal bridging” – pathways where heat can easily escape through the structure. This comprehensive insulation ensures a consistent internal temperature, enhancing comfort and efficiency.

Rapid Construction / Installation Panel

Time is money in construction, and sandwich panels are champions of speed. Their prefabricated nature dramatically cuts down on construction time.

- Factory-Made Precision: Sandwich panels are manufactured in a controlled factory environment. This means they arrive on site ready to be installed, cut to precise dimensions, and finished. There’s no need for on-site cutting or complex layering.

- Faster Erection Times: Because the panels are large, lightweight, and pre-finished, they can be installed much faster than traditional building methods like brick and mortar or multi-layer roofing systems. A whole wall or roof section can be put up in a fraction of the time. This ease of installation panel is a major draw for project managers.

- Reduced Labor Costs and Project Timelines: Faster construction means fewer hours for labor, directly leading to lower labor costs. It also means projects can be completed sooner, allowing businesses to start operating or residents to move in earlier. This accelerated building process makes assembly panels incredibly attractive for timely project delivery.

- All-in-One Solution: Each sandwich panel often acts as an exterior finish, insulation, and interior lining all in one unit. This reduces the number of steps and different trades needed on site, streamlining the entire construction process.

Lightweight and High Strength

It might seem contradictory, but sandwich panels offer an impressive combination of being both lightweight and incredibly strong.

- Excellent Strength-to-Weight Ratio: The “sandwich effect” is a brilliant engineering principle. By separating two strong outer skins with a lighter core, the entire panel gains significant rigidity and strength without adding much weight. This means a relatively thin composite panel can be very strong and resist bending.

- Reduced Load on Foundations and Structure: Because the panels themselves are light, they impose less weight on the building’s foundations and the main structural framework (like steel beams or concrete columns). This can lead to smaller, less expensive foundations and a lighter, more economical supporting structure, saving costs across the board.

- Easier Handling: The lightweight nature also makes transportation, lifting, and positioning of the panels on site much simpler, requiring less heavy machinery and fewer workers.

Durability and Longevity

Buildings are long-term investments, and sandwich panels are designed to stand the test of time.

- Resistance to Weathering: The outer facings, particularly those made from PPGI, stainless steel, or aluminum, are highly resistant to harsh weather conditions, including rain, wind, and UV radiation. They protect the core and maintain their appearance for many years.

- Corrosion Resistance: Depending on the facing material (e.g., galvanized steel, stainless steel, or aluminum), sandwich panels offer excellent resistance to corrosion, which is vital in industrial environments or coastal areas.

- Minimal Maintenance: Once installed correctly, sandwich panels generally require very little ongoing maintenance. Their surfaces are often easy to clean, and the robust construction means fewer repairs compared to some traditional building materials. This translates into lower lifecycle costs for the building.

Aesthetic Versatility

Beyond their functional benefits, sandwich panels also offer considerable design flexibility, catering to modern architectural styles.

- Wide Range of Colors and Finishes: The facings can be painted in virtually any color, allowing architects to match corporate branding or create striking visual designs. Different finishes, such as smooth, ribbed, or micro-ribbed, also add textural interest.

- Various Profiles: Panels come in different profiles and shapes, offering design variations for walls and roofs. This allows for creativity in building facades, from sleek, flat surfaces to more textured looks.

- Modern Appearance: Sandwich panels can give buildings a clean, contemporary, and professional look, making them popular for commercial and industrial structures that want to project a modern image.

Cost-Effectiveness

While the initial purchase cost of sandwich panels might sometimes seem higher than very basic traditional materials, their long-term economic benefits often make them a more cost-effective choice overall.

- Long-Term Energy Savings: The significant reduction in heating and cooling costs is a major ongoing saving that quickly offsets the initial investment. These thermal efficient panels are a financial asset.

- Reduced Construction Time and Labor: As discussed, faster installation panel processes lead to lower labor expenses and allow for earlier occupancy or operation, generating revenue sooner.

- Lower Maintenance Costs: The durability and robust nature of the panels mean less money spent on repairs and upkeep over the years.

- Potential for Smaller Structural Elements: The lightweight nature can lead to savings in the building’s primary structure and foundations.

In conclusion, the widespread adoption of sandwich panels is no accident. They offer a compelling blend of superior thermal performance, rapid construction capabilities, remarkable strength for their weight, excellent durability, versatile aesthetics, and long-term cost-effectiveness. These modular building panels are a smart choice for anyone looking to build efficiently, sustainably, and for the future.

The Installation Process: Ensuring Optimal Performance

Even the most advanced sandwich panels will not perform to their full potential if they are not installed correctly. The installation panel process is a critical step that ensures the building achieves its promised thermal efficiency, structural integrity, and longevity. Proper installation is key to unlocking all the benefits these insulated panels offer. It’s not just about putting pieces together; it’s about precision and attention to detail.

Pre-installation Checks: Laying the Groundwork

Before a single sandwich panel is lifted, careful preparation is essential. This stage is all about ensuring everything is ready for a smooth and accurate installation.

- Verification of Structural Readiness: The first step is to confirm that the building’s main steel or concrete structure is complete, stable, and plumb (perfectly straight up and down). The supporting framework must be aligned correctly to ensure the panels fit precisely. Any deviations in the main structure can cause problems with panel alignment and sealing later on.

- Panel Dimensions and Quantity: All panels should be checked against the project drawings to ensure they are the correct size and quantity. A detailed inventory helps avoid delays caused by missing or incorrect panels.

- Site Preparation: The installation area needs to be clear, clean, and safe. This includes ensuring proper access for lifting equipment and storage areas for the panels.

- Tools and Equipment: All necessary tools, fastenings, sealants, and safety equipment must be on hand before installation begins. This preparation prevents interruptions once the work has started.

Lifting and Positioning: Precision and Safety

Moving and placing large, often heavy, sandwich panels requires specialized techniques and equipment to ensure they are handled safely and without damage.

- Specialized Lifting Equipment: For large wall and roof panels, vacuum lifters are often used. These devices create a powerful suction cup effect, securely holding the panel without hooks or clamps that could dent or scratch the surface. Cranes are also used to hoist the panels into position.

- Safe Movement: Panels must be lifted and moved carefully to prevent bending, twisting, or damaging the edges and surfaces. Even minor damage can compromise the panel’s insulation or aesthetic appeal. Proper lifting points, as recommended by the manufacturer, must always be used.

- Accurate Placement: Each panel is meticulously guided into its exact position. This often requires skilled operators working in coordination, ensuring panels are perfectly aligned with adjacent panels and the building structure. This careful panel placement is vital for proper fit.

Fastening: Securing the System

Once positioned, the sandwich panels must be securely attached to the building’s supporting structure. The method of fastening is crucial for the panel’s stability and resistance to wind loads.

- Primary or Secondary Structure: Panels are typically fastened to either the primary steel or concrete framework, or to a secondary support system like purlins (for roofs) or girts (for walls).

- Self-Drilling Screws: These are a common fastening method. They drill their own pilot hole, tap threads, and fasten the panel in one operation, often with a washer that seals the hole.

- Blind Rivets: Used in specific applications, rivets provide a secure, flush fastening.

- Concealed Fixings: For a cleaner, more aesthetically pleasing finish, some sandwich panel systems use concealed fixings, where the screws are hidden within the panel joint. This method gives a smooth, uninterrupted exterior surface.

- Correct Fastener Selection: The type, length, and spacing of fasteners are critical and must comply with engineering specifications and local building codes, taking into account wind loads and the type of structure.

Sealing and Joints: The Thermal Barrier’s Integrity

The joints between sandwich panels are the most vulnerable points for heat loss and water ingress. Proper sealing is absolutely critical for the long-term performance of the entire insulation panel system.

- Preventing Air Leakage: Air leakage through joints can drastically reduce the thermal performance of even the best insulation panels. Sealants, gaskets, and specialized joint profiles are used to create an airtight barrier.

- Water Ingress Protection: Rainwater must be prevented from entering the building envelope. This is achieved through overlapping panel profiles, gaskets, and high-quality sealants applied to all external joints.

- Thermal Breaks at Joints: Care must be taken to ensure that metal-to-metal contact at joints does not create “thermal bridges” where heat can easily pass through. Gaskets or non-conductive shims are often used to maintain the thermal barrier.

- Specialized Flashing Systems: For corners, roof ridges, eaves, and penetrations (like windows or doors), specialized flashing systems are installed. These are custom-bent metal pieces that provide a robust, weather-tight, and aesthetically pleasing finish, ensuring continuous protection. The careful application of joint sealants is paramount for a high-performance building envelope.

Importance of Professional Installation: Maximizing Performance

While the steps might seem straightforward, the devil is in the details. Professional installation is not just a recommendation; it’s an investment in the long-term performance and efficiency of your building.

- Experienced Installers: Trained and experienced installers understand the nuances of different sandwich panel systems. They know how to handle the panels without damage, achieve perfect alignment, and apply sealants effectively.

- Proper Alignment: Accurate alignment ensures panels fit snugly, minimizing gaps and maximizing the thermal envelope. It also contributes to the aesthetic quality of the finished building.

- Effective Sealing: Professional installers ensure that all joints are sealed completely and correctly, preventing air and water penetration. This is crucial for maintaining the intended insulation values and preventing moisture-related problems.

- Structural Connection: Experts ensure that panels are securely and properly fastened, providing the necessary structural connection to resist environmental forces like wind and seismic activity.

- Warranty Compliance: Many manufacturers require professional installation for their product warranties to be valid. This underscores the importance of proper execution.

Ultimately, a meticulously performed installation panel process guarantees that your sandwich panel system will deliver its promised benefits: superior thermal insulation, robust structural integrity, and a long, low-maintenance lifespan. Skimping on installation can lead to costly problems down the road, compromising the very advantages these advanced building materials are designed to provide.

Common Applications of Sandwich Panels

The versatility and high performance of sandwich panels mean they are found in an incredibly diverse range of buildings across many industries. Their ability to provide excellent insulation, rapid construction, and durability makes them a go-to solution for specific needs, particularly where temperature control and efficiency are paramount. These modular building panels are truly transforming how we construct various facilities.

Industrial Buildings: Efficiency at Scale

Industrial facilities, often large in scale, greatly benefit from the speed and performance of sandwich panels.

- Warehouses: For storing goods, particularly those sensitive to temperature, sandwich panels provide the necessary insulation to maintain stable internal conditions, protecting inventory. The rapid installation panel process means warehouses can be built and operational much faster.

- Factories and Manufacturing Plants: These buildings often require precise internal temperatures for machinery or processes, as well as robust, easy-to-clean surfaces. Sandwich panels, especially those with PU cores, offer excellent thermal regulation and a durable finish. They also contribute to a quieter environment due to their acoustic properties.

- Power Plants: For various sections of power generation facilities, sandwich panels can provide thermal and acoustic insulation, as well as fire resistance (especially with mineral wool cores).

Commercial Buildings: Modern Aesthetics and Comfort

From bustling shopping centers to sleek office spaces, sandwich panels contribute to both the function and appearance of commercial structures.

- Shopping Malls: Their rapid construction helps bring projects to market faster, while their insulation properties ensure a comfortable environment for shoppers. The aesthetic versatility allows for modern, attractive facades.

- Office Complexes: Sandwich panels contribute to energy-efficient office spaces, reducing utility costs and providing a comfortable working environment for employees. Their clean lines and variety of finishes offer a contemporary look.

- Exhibition Centers: Large, open spaces like exhibition centers benefit from the wide spans and structural integrity that sandwich panels offer, along with effective thermal management for various events.

Cold Storage & Refrigeration: The Ultimate Requirement

This is perhaps the most critical application for sandwich panels, particularly those with PU panels. Maintaining consistent low temperatures is non-negotiable here.

- Cold Rooms and Freezer Rooms: Absolutely essential for storing perishable goods like food, pharmaceuticals, and chemicals, these rooms rely entirely on superior insulation. PU panels are the preferred choice due to their exceptional thermal insulation properties, which prevent heat ingress and minimize energy consumption for refrigeration. These refrigeration panels are specifically designed for demanding, low-temperature environments.

- Food Processing Units: In facilities where food is prepared, processed, and packaged, strict temperature and hygiene standards are required. PU panels provide the necessary insulation and often come with food-safe facings (like stainless steel or FRP) that are easy to clean and sanitize.

- Logistics Hubs: Large-scale distribution centers that handle refrigerated goods depend on PU panels to create vast temperature-controlled zones, ensuring the integrity of the cold chain.

Clean Rooms: Controlled Environments

Industries requiring highly controlled environments find sandwich panels indispensable.

- Pharmaceutical Manufacturing: Creating sterile, temperature- and humidity-controlled environments for drug production is crucial. Sandwich panels provide the clean, smooth surfaces and precise insulation needed.

- Electronics and Semiconductor Manufacturing: These facilities require incredibly clean, static-controlled environments. sandwich panels with specialized facings and sealing systems help maintain these stringent conditions.

- Medical Facilities and Laboratories: For operating theaters, research labs, and sterile storage areas, sandwich panels offer hygienic, easy-to-clean surfaces and stable environmental control.

Agricultural Buildings: Protecting Livestock and Produce

In the agricultural sector, sandwich panels offer practical, durable solutions.

- Animal Housing: For livestock buildings, proper insulation helps maintain comfortable temperatures, improving animal welfare and productivity. The panels are easy to clean, contributing to better hygiene.

- Storage Facilities: For crops, feed, or equipment, insulation panels protect against extreme temperatures and moisture, preserving quality and extending shelf life.

Modular Buildings and Prefabricated Homes: Speed and Efficiency

The rise of modular construction has seen sandwich panels become a foundational element.

- Prefabricated Housing: The speed of construction and the inherent insulation panels benefits make them ideal for factory-built homes and temporary accommodation. Whole sections of homes can be assembled off-site and quickly erected.

- Temporary Offices and Site Buildings: For construction sites or rapid deployment needs, modular buildings made with sandwich panels offer quick setup, good insulation, and ease of relocation. For construction sites or rapid deployment needs, modular buildings made with sandwich panels offer quick setup, good insulation, and ease of relocation.

The wide array of applications truly showcases the adaptability and effectiveness of sandwich panels. Whether it’s to keep vaccines cold, factory workers comfortable, or a new building rapidly constructed, these innovative building envelope systems provide a high-performance solution for almost any modern building challenge.

Conclusion

In wrapping up our journey through the world of sandwich panels, it’s clear that these are far more than just simple building blocks. They represent a significant leap forward in construction technology, offering a versatile and incredibly efficient solution for a multitude of building needs. We’ve seen how a sandwich panel is ingeniously designed with its layered structure: strong outer skins protecting a high-performance core, working together as a formidable composite panel.

Their primary advantages are truly compelling. From offering robust insulation panels that dramatically reduce energy consumption – especially with advanced materials like PU panels – to enabling incredibly rapid construction through their efficient installation panel process, they stand out in the building materials landscape. They deliver not just strength and durability but also aesthetic flexibility and long-term cost savings.

Whether the goal is to create a deeply insulated cold room that meticulously preserves its contents, a sprawling warehouse that rises in weeks, or a modern office block that keeps its occupants comfortable and energy bills low, sandwich panels offer significant benefits over more traditional construction methods. Their ability to deliver superior thermal performance, combined with their quick assembly and inherent robustness, makes them an incredibly smart choice.

Ultimately, sandwich panels are not just about building; they’re about building smarter. They embody a commitment to sustainable practices, providing cost-effective and high-performance building solutions that are crucial for the future. As we continue to seek ways to construct more efficiently, save energy, and create durable, comfortable spaces, sandwich panel technology will undoubtedly remain at the forefront, shaping the skylines and interiors of tomorrow’s world.